Spray down the bolt head and any portion of the threads you can gain access to with a penetrating oil. Different types and strengths of thread-lock are used for different applications and screw types.

Generally speaking heat apply to the screw helps to loosen most thread-lock material.

How do you stop a bolt from stripping. Can you fix stripped threads. The complete repair for stripped threads is to use a coil-type thread insert. These inserts will give the bolt hole completely new threads which accept the size of the original bolt.

In order to use inserts you must drill the damaged holes slightly larger so that it can take the thread insert. This is another one to try early in the process and in-conjunction with other methodsUsing a ratchet and socket slowly work the bolt or nut back and forth. Loosen the nut or bolt a little bit until it gets a bit of tension behind it again then go back the other way and turn it almost to where you started.

In some cases like when working on your car screws might have a specific torque that should be applied when screwing them in to prevent stripping and overtightening. If thats the case you will want to get a torque screwdriver that will let you adjust the torque with precision. If a Screw Starts Stripping Stop Immediately.

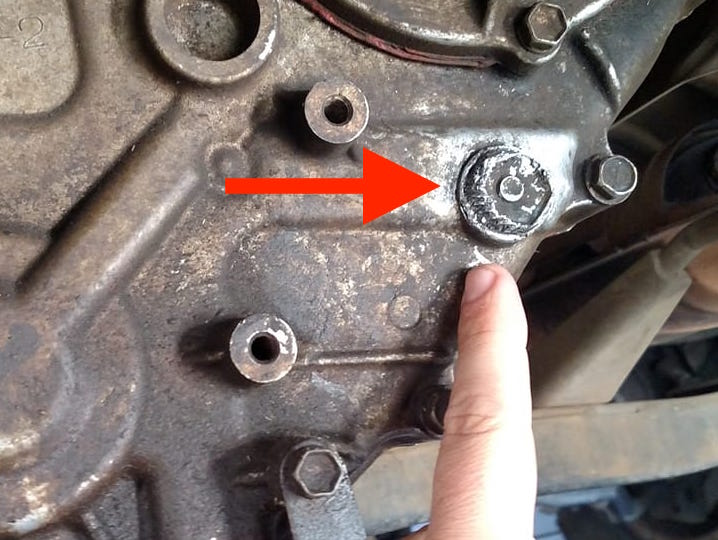

Spray down the bolt head and any portion of the threads you can gain access to with a penetrating oil. In most cases where a bolt has become stripped it is due to threads that have become locked from rust or corrosion. Penetrating oil will remove some of this rust and lubricate the threads.

Heat the bolt with a propane torch if its still stuck. If the bolt doesnt budge when you try loosening it with the extended wrench its time to try using heat to un-stick the bolt. Turn on a propane torch and hold the flame about 12 inch 13 mm away from the bolt.

Keep the flame on the bolt for about 15 seconds. Use the tap attached to the tap handle over the stripped bolt hole. If the hole was made by right-hand screws insert the tap into the hole while rotating it clockwise.

If its a left-hand hole rotate anti-clockwise. Nearly all holes screws and bolts are right-hand screws. However there can be exceptions.

Answer 1 of 2. Different types and strengths of thread-lock are used for different applications and screw types. Smaller or phillips head screws can be quite difficult to get loose withought stripping the head.

Generally speaking heat apply to the screw helps to loosen most thread-lock material. In this video I go over your options on as far as what you can use to remove and replace a rounded off bolt or nutPittsburgh Bolt Extractor Metric. How to Avoid Spinners.

With the right technique you can save yourself the trouble of dealing with spinning bolts. Before drilling blow or use a tiny piece of cloth to clean the hole out completely. Make sure you use the right drill bit and drill straight.

Holding the drill at an angle will secure the bolt in place. Measures that can be taken to prevent bolt failures. Assessing the design of the component or the structure upon which it is going to be used thereby accurately calculating the amount of force that would be acting on the bolt.

Assessing the environment where the bolt is going to be used and applying the right coatings to avoid corrosion. Square Off the End of the Driver With Disc Sander. Turn the disc sander on and then using the table to rest the drill on hold the drill at a 90 degree angle to the disc sander face and carefully flatten the point off of the driver end.

To quickly mitigate the effects of slipping simply take your favorite roll of painters tape and wrap the bit with it. This will make the drive fit more securely to help deter that slide out effect while also protecting the head of the screw in the event of a slip out. Make sure the bit fits the screw really well and is in good condition.

Dont rely on just your hand and forearm strength to hold the bit in the screw - get your face close to the part youre working on and position your body so you can throw some weight into it. Make sure the driver is in line with the screw. Tighten the pipe wrench down on the boltnut and as you crank on the bolt with the pipe wrench it actually grabs harder onto the bolt head.

Just watch you knuckles if it slips off. Reinstall Bolts That Surround the Stuck BoltNut Sometimes a number of bolts in an area will hold a part on. Occasionally these are meant to be removed in.

The idea is to keep that clutch low enough so that you cant apply more torque than the screw can handle. If you need more torque the drill will ratchet harmlessly instead of stripping your screw. When it happens then I usually reposition myself to apply more force and then turn the torque up.

Heres Emmons five-step plan to avoid screwing up. To keep screws from seizing up in wood first drill a hole to the same depth as your screw with a bit barely thinner than the screws shank. Use a Fresh Driver Bit.

Squeeze the Trigger Firmly. Keep the Pressure On. Should I pre drill holes for deck screws.

Knowledge of the thread stripping strength of tapped holes is necessary to develop full tensile strength of the bolt or for that matter the minimum engagement needed for any lesser load. Conversely if only limited length of engagement is available the data help determine the maximum load that can be safely applied without stripping the threads. Two nuts can be used to reduce the risk of thread stripping especially if the threads are galvanised.

Hence there may be a good reason to use two nuts ie. To ensure that the full strength of the bolt is developed rather than a premature failure from thread stripping. With the absence of the oxide coating the raw metal threads contact each other directly with no barrier causing the the nut and bolt to fuse together.

Prior to use you inspect all fasteners yet after installation they still fail. So how do you prevent this. Galling Prevention 1 Install Slowly and Correctly.

If you still cant get it loose grab a propane torch and put some heat on the part. You can try heating up the surrounding threads or concentrate on the bolt. Once it is good and hot hit it with some penetrating oil.

This will shock the hot metal breaking the threads grip allowing you to free the bolt. The first thing you will need to do is remove the bolt. If the hole is completely stripped and you cannot get enough grip to remove the bolt you will need to drill into the center of the bolt and have a bolt extractor on hand to remove it.

One way to keep your bit from camming out of the fastener is to make sure that youre using the right size bit. Matching the bit to the screw youre trying to turn makes a world of difference. When youre checking set the bit in and give a wiggle.

There shouldnt be much play. If there is go to the next larger size. While these devices do prevent the nut from falling off the bolt they generally do not help the joint maintain the specified clamp force.

Nylon or metal inserts inside a nut sometimes called a lock nut can add extra friction to prevent loosening. A related idea is to fit a spring inside the nut which firmly. Put the nozzle of the wood glue bottle into or as near to the hole surrounding the screw as possible and squeeze the glue bottle allowing wood glue to fill the hole.

If the glue fails to hold the screw move to the next step and use the denser wood putty. 7 Ways to Prevent Thread Galling. 7 Ways to Prevent Galling.

1 Use Proper Lubricants. Pre-applied or applied on site dry film lubricants or lubricants rich in molybdenum disulfide moly graphite mica talc and even extreme pressure waxes are effective at reducing friction. Brand names include Perma-Slik RAC Xylan and DELTA SEAL.

Fluoropolymer coatings are also effective.