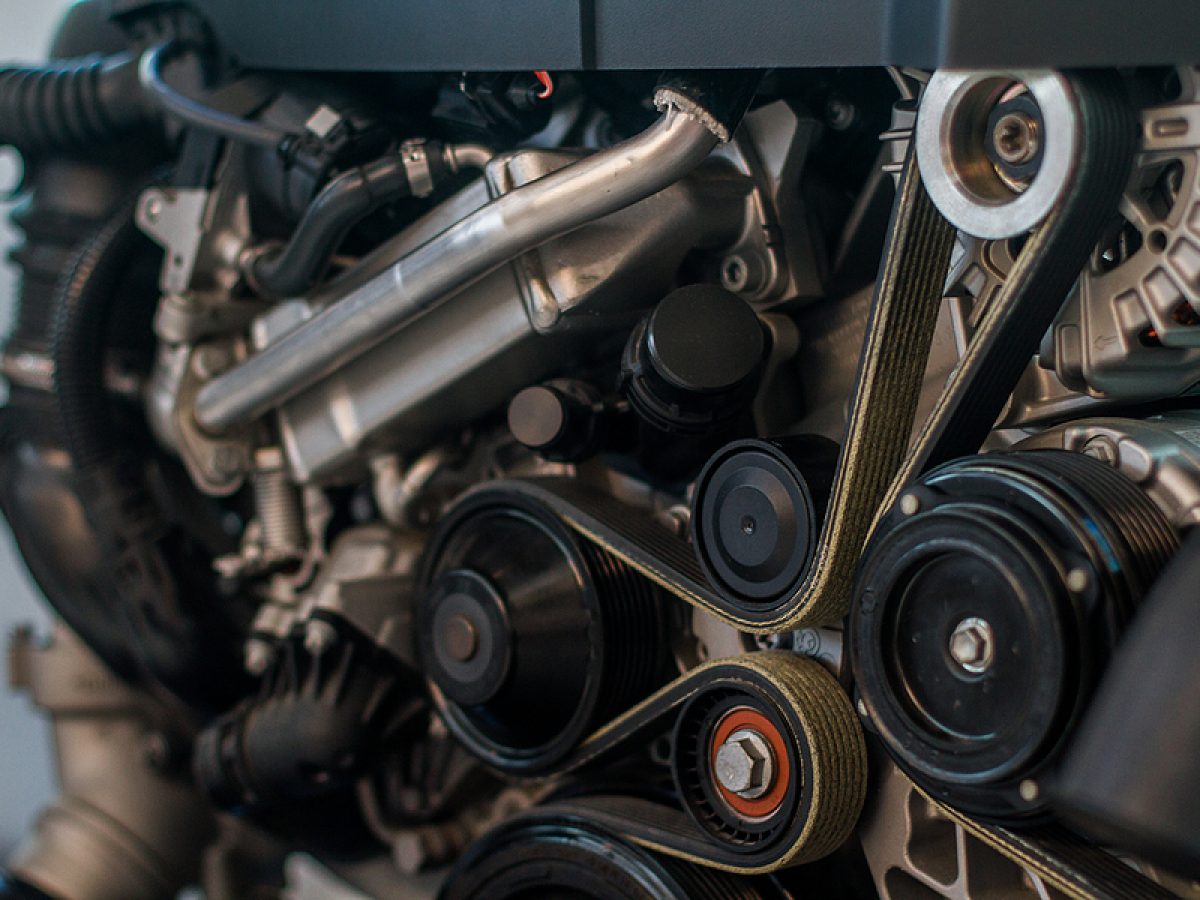

Check the tension of the belt periodically. How tight do you tighten serpentine belt.

How tight should a mower deck belt be.

How tight should serpentine belt be. The required measure of tension in the serpentine belt is that it should not deflect more than ½ inch when twisted either way from the middle. If twisted more the belt is loose and if twisted less the belt is too tight. Either of the positions does not work for the vehicle.

So how tight should serpentine belt be. It should be in a middle range that is highly suitable for your engine system. Ideally it shouldnt bounce more than o5 inches.

How tight should a serpentine belt be. The required measure of tension in the serpentine belt is that it should not deflect more than ½ inch when twisted either way from the middle. If twisted more the belt is loose and if twisted less the belt is too tight.

How tight do you tighten serpentine belt. The required measure of tension in the serpentine belt is that it should not deflect more than ½ inch when twisted either way from the middle. If twisted more the belt is loose and if twisted less the belt is too tight.

Click to see full answer. I just bought this car and the belt seems very tight. There is no difection and ther is a slight humming noise from the engine area which I cant pin point.

James Ford Technician replied 7 years ago. Is the serpentine belt too tight in a car. That said the serpentine belt should not be too tight also in the engine system.

Otherwise the strain it will put on the pulleys and connecting bearings will be more eventually consuming more power than required in the running. The belts should have flex in them and not too tight. I just changed mine on the Tacoma and my Tundra and they were within spec on the flex of the belt.

If they are too tight it will cause bearing issues among other things. How tight should belts be. The required measure of tension in the serpentine belt is that it should not deflect more than ½ inch when twisted either way from the middle.

If twisted more the belt is loose and if twisted less the belt is too tight. An expert who has achieved level 1. Serpentine belt too tight to install.

Make sure you have loosened the tension bolt ENTIRELY. They can go REALLY loose so you can easily install the belt. You should be able to see how much more you can loosen it by looking at the backside of the bolt.

Here is how I check belt tension on a serpentine belt. Go to the long side of the belt and grab the belt with your hand. If you can twist the belt around past the halfway point meaning the ribs are actually facing upwards it is too loose.

2If you cant twist the belt at all it is too tight. Get a 516 sockety and put it on the small nutcrank it until it ratchets up to the top of the channel and gets the belt tight. While holding that tight take a 58 wrench and tighten the big nut behind itYou should be good to go.

Twisting the belt was a method I read about in several posts found through googling I wasnt sure how to measure the deflection. Ive now put a ruler along the belt and pressed down at the points indicated A and B in the diagram and the deflection on A is 8-9mm and about 11-12mm on B so looks like I should tighten the AC belt a bit more. Jun 27 2014 The chiltons calls for using a serpentine belt tensionmeter to set the correct tension which is 180-200 lbs on a new belt and 140-160 lbs on a used belt.

That said Ive only worked at one shop through the years that had this tool and through using it I found that you can pretty much use the 12 of deflection between the longest length of. The belt should have about a half an inch of play when at the appropriate tightness. If there is less than a half an inch the belt will need to be loosened if there is more it will need to be tightened.

You want a maximum of 8mm deflection on the main drive belt. Any more than that and you need to re-adjust the system. You need to verify the squeek at a normal RPM of the engine.

Use a piece of hose to isolate the noise. A half an inch of slack between to pulleys when pushed down is valid and could even be at a quarter of an inchA mis aligned pulley can also cause a squeeky belt. Under no circumstances will proclaimliberty2000 be responsible or liable in any way for any content including but not limited to any errors or.

Check the tension of the belt periodically. To do this grab any area of the belt that is between two pulleys with your fingers. There should be approximately 14 inch play in the belt for most vehicles.

Serpentine belts stretch with age and use but the tensioner is spring-loaded to keep the belt tight on the pulleys. If a belt starts slipping the tensioner should always be checked to see if it is functioning properly. There should be no binding or resistance and the pulley should spin smoothly.

How do I know if my serpentine belt is tight enough. The required measure of tension in the serpentine belt is that it should not deflect more than ½ inch when twisted either way from the middle. If twisted more the belt is loose and if twisted less the belt is too tight.

How tight should a mower deck belt be. Roughly starting out about as tight as an alternator belt maybe an inch of play side to side So tight but not super tight hard to explain it just takes practice. Too tight is no good I find if its tight enough where it doesnt slap around at all then its also too tight aint life grand.