Jack the Rear Wheel Up. Pry the seal out of the hub with a screw driver or suitable tool.

Start off by getting the wheel off the ground and checking to see if there is any play top to bottom and side to side.

How to check hub bearings. To check a hub bearing assemblys internal clearance a dial indicator with a magnetic base is required. To obtain accurate readings from the dial indicator it is important to thoroughly clean and smooth the surfaces where the dial indicator base and tip will be placed. Check the hub bearing assemblys internal clearance using a dial indicator with a magnetic base.

For an accurate reading thoroughly clean and smooth the surfaces where you will place the dial indicator base and tip. Use a fine file wire brush emery cloth or honing stone. Steps of Checking Wheel Bearing.

The steps of checking wheel bearing are given bellow. Jack the Rear Wheel Up. You have to check the manual instructions of the vehicle and follow the steps to jack up the car.

In this process you will need a car jack to go through the whole process. The second step is to hold the wheel. Often times an owner is told by a mechanic they have a bad wheel bearing.

Mark shows you how he troubleshoots a wheel bearing on Toyota Yaris Corolla and Ca. Listen for any unusual noise and feel for any roughness as it rotates which may indicate that the bearing is damaged and needs to be replaced. Shift back into Park for an automatic transmission or gear for a manual transmission before lowering the vehicle to the ground.

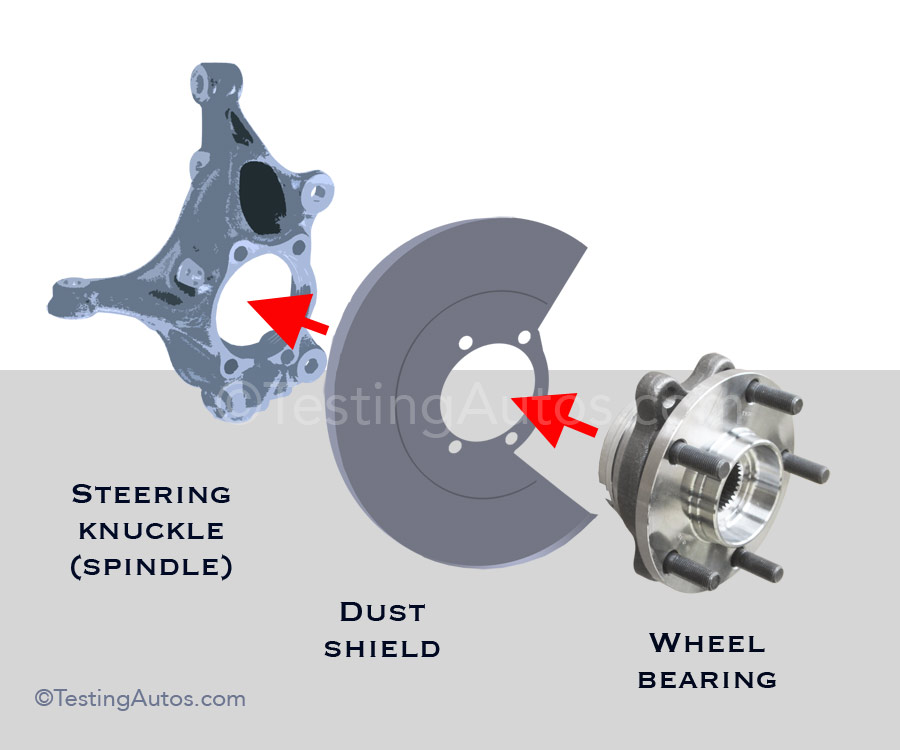

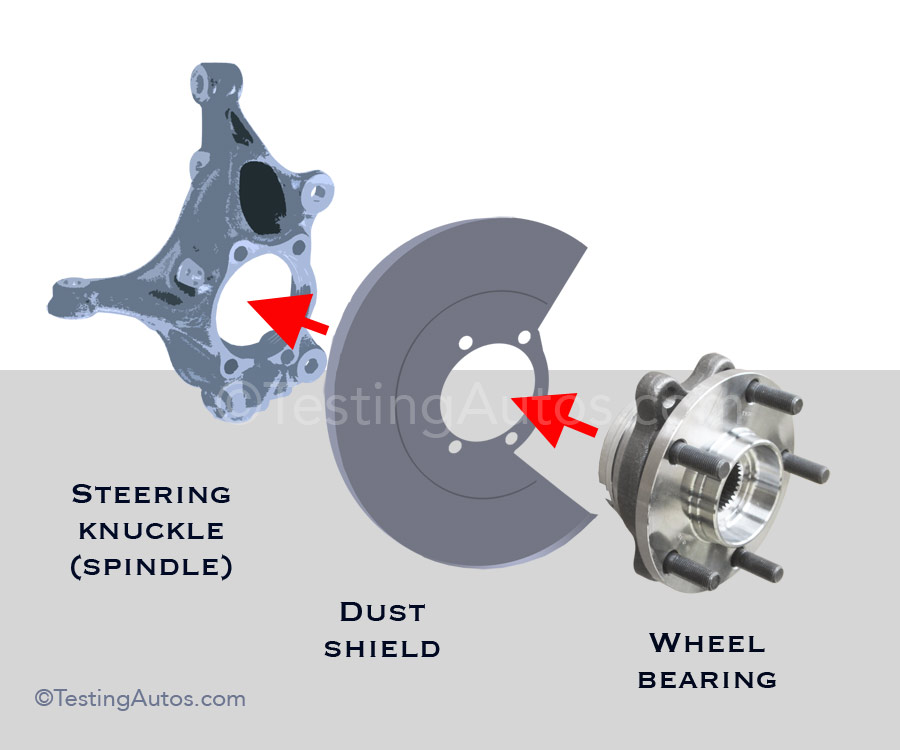

Place the stethoscope tip on knuckle the portion the wheel bearing is inside of NOTE. You may need to take the caliper and rotor off of the hub to get a clear shot at the knuckle. Turn the hub and listen.

When you are listening you should be able to tell pretty quickly if it has the bad bearing or not. It will sound crunchy as you are turning it. A good bearing should sound relatively smooth as you turn the hub.

Doing Your Own Hub Assembly Check. Fortunately a damaged hub assembly is easy to spot once you have your wheels jacked up off the ground. If at all possible check your wheels two at a time either both front wheels or both back ones.

You can often spot a broken wheel bearing simply by comparing the behavior of two wheels after you spin them at the same time. There are ways to tell if you need to replace hub bearings. Drive your car by yourself in a low traffic area with the radio and air vent fan turned off and listen for noise.

A whine squeak chirp squeal or moan coming from the direction of a wheel while driving or a grinding noise when turning can indicate a worn hub bearing. When bearings are inspected the appearance of the bearings should first be recorded and the amount and condition of the residual lubricant should be checked. After the lubricant has been sampled for examination the bearings should be cleaned.

In general light oil or kerosene may be used as a cleaning solution. The best test for checking the condition of hub bearings is done by removing the wheels. With the wheel off the bike its easy to hold the axle and inspect its parts and.

Check for any play. Start off by getting the wheel off the ground and checking to see if there is any play top to bottom and side to side. Do this by grabbing the outside of the tyre and giving it a bit of wiggle top and bottom and both sides.

If there is any movement your wheel bearings are. This is how to tell which wheel bearing is bad by turning as the opposite side of the turn is the affected area. A clicking sound also demands attention as it is likely to come from a broken bearing in the hub assembly.

If a bearing is the culprit the noise turns faster with acceleration. To identify which bearing is responsible reduce the. Shimano hubs normally use loose ball bearings but they are not bad at all.

Just wait for juhist he will surely explain to you in many details Cup and cone bearings however require to be periodically set to the right preload. It is not difficult at all and does not have to be done way too often. Bike shops will do it in their routine check-ups.

Drive the vehicle while listening for any possible noises from your hub bearings. After your test drive park the vehicle. Then point your infrared thermometer or thermal camera at each of the wheel hub areas one at a time.

If one wheel hub assembly is significantly hotter than the others you may have found the bad bearing. Use a dial indicator. Pry the seal out of the hub with a screw driver or suitable tool.

Do not drive it out. Inspect and clean the bearings along with the spindle with a solvent and dry them. Make sure to inspect the bearing inside the hub.