Rislone Compression Repair with Ring Seal works two ways to solve low compression problems. Use a compression gauge to check the measurement.

One further recommendation would be to add a set of mid-length headers to the engine.

How to fix compression in cylinder. Find the prime suspect for low compression. See the causes above What can cause low compression in one cylinder Make sure to repair or replace the damaged part. In most cases the timing belt might be the problem.

You can fix this by pouring some oil into the cylinder. If this works you may have also fixed the problem in the piston rings. Your cars low compression can be triggered by a number of mechanical problems.

Even if youre wondering how to fix low compression in one cylinder for an outboard engine you can trace the problem back to these causes as well. They can all be fixed. If your gasket isnt aligned properly or is dilapidated it can cause low compression in one cylinder.

If you dont have the time or budget for a physical hard part repair your next step should be adding an engine compression restoration treatment product such as Rislone Compression Repair with RingSeal to your engine. While a product like this does not guarantee you will never have a compression issue some compression issues are too severe and a hardware fix is the only repair option it can make it much less likely by unsticking rings and filling cylinder. One can do a compression test on the suspected cylinders squirt some oil in the cylinder and repeat the test.

If the compression doesnt increase the problem most likely is in the valves. If the compression reading increases then the piston rings are suspect. How to Fix Low Compression in One Cylinder.

The first step to repair is to be sure that the compression in One of the engine cylinders is low. Use a compression gauge to check the measurement. In case you dont have one Take the car to an auto servicing shop.

So a mechanic can do the testing. If you find low compression the next step is to check the cylinder Valves gasket. To begin check for no compression in one of the cylinders with a compression gauge.

Make sure you have enough time to complete the exam as it will take about 40 to 45 minutes. Examine the cylinder gasket valves and piston to check if any of these components are broken or damaged after verifying that one of the cylinders has no compression. Isolate and address the cause.

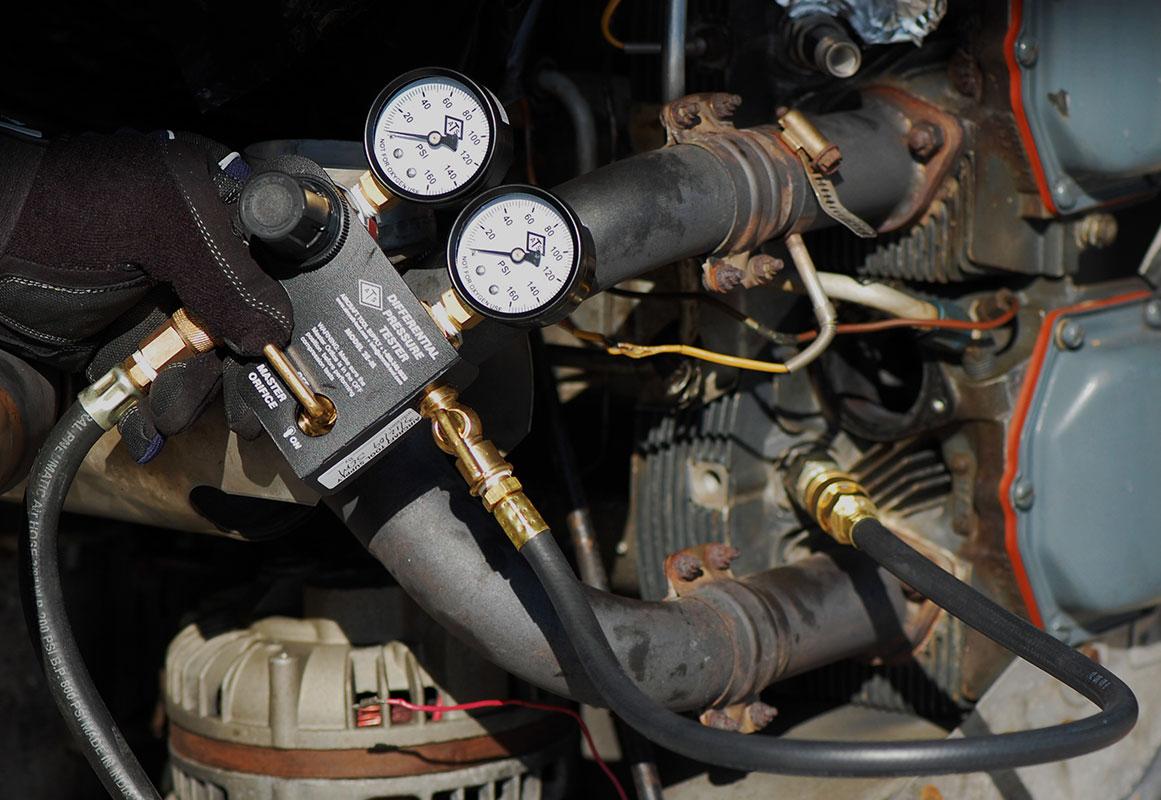

Typically a compression check has already been performed in order to establish the problem. The next step is a leak down test pressurizing the cylinder with compressed air through the spark plug hole with the piston at TDC on compression both valves closed and. Rislone Compression Repair with Ring Seal works two ways to solve low compression problems.

First chemical polymers work to fill in scratches and grooves in cylinder walls caused by normal wear age and high mileage. Secondly frees sticking rings in piston grooves to allow the rings to properly seal increasing compression. Low compression indicates damaged or stuck compression rings.

These rings are installed in the piston grooves. Due to their elasticity they fit tightly against the cylinder walls but a ring can break. The compression is measured with a peak pressure gauge.

You can install it. How To Fix A Lawn Mower With No Compression - Video - YouTube. First ensure the camshaft is at the point where the valves are shut.

Apply pressure into the cylinder and listen keenly for any compression leaking. It could be leaking into the crankcase intake or exhaust. If you hear any leaks then you have low compression in that cylinder.

There are some relatively minor repairs that you can make to fix a low compression problem in a cars engine. For instance replacing bad piston rings will usually only cost somewhere between 40 to 200 per piston ring. But thats going to be among the most affordable repairs for those with low car engine compression.

First measure the compression of the cylinders using a compression tester. Keep in mind to specifically check for gasket readings and see whether its different than normal. If it shows to be problematic then shut your engines off and stay away from releasing pressure.

The easiest way to improve compression is with a set of 64cc chamber cylinder iron Vortec heads and that 0015 head gasket which will push the compression up to 901. One further recommendation would be to add a set of mid-length headers to the engine. This will do more to add power than any other thing you can do.

As the piston moves downward it creates low pressure or partial vacuum in the cylinder. Outside air pressure forces airfuel mixture and injection in through the open intake valve. To Increase Compression Ratio you should understand car features and also how the different parts acts for powering up the engine.

The easiest way to improve compression is with a set of 64cc chamber cylinder iron Vortec heads and that 0015 head gasket which will push the compression up to 901. One further recommendation would be to add a set of mid-length headers to the engine. We removed the valves and the liner then subjected the cylinders cooling water space to water and helium leakage testing.

Unfortunately this did not locate the exact position of the leak. However when the gas side of the cylinder was pressurised to 50 bar a leakage path between the gas and the cooling water sides was clearly seen. It really depends why blown head gasket damaged valves weak piston compression rings take a compression of cylinder record reading then put 4 ounces of engine oil into the cylinder and test again if the compression comes up to were it should be its the piston and if it only has a minor change it is the valves or head gasket put 100 psi of air pressure into the cylinder on compression stroke and listen.

If low compression is caused by fuel leaking into cylinders it will help to put a little oil in the cylinders. Before you do this remove the spark plugs and set them out to dry. Once they are dry put in some oil then put them back in place and try to start the engine.

In this video I demonstrate how to make and use a compression tester on your engine cylinder. I also show how to use the same compression gauge to do a lea. Cracked cylinder walls can cause low engine compression as the cylinder chamber must be airtight to keep the gasses from escaping.

The pistons piston rings and cylinder walls all play a part in keeping the cylinder compression from escaping. A common cause of cracked cylinder.