To begin use a compression gauge to determine whether one of the cylinders has no compression. In most cases the timing belt might be the problem.

No Engine Compression In One Cylinder Dropped Valve Seat.

How to fix no compression in one cylinder. Yes a dead cylinder can be fixed by checking and rectifying any defective component that falls among some of the reasons that result in a dead cylinder. In order to fix a dead cylinder you will have to diagnose the cylinder by using a compression gauge to test whether there are any cylinders with no compression. Find the prime suspect for low compression.

See the causes above What can cause low compression in one cylinder Make sure to repair or replace the damaged part. In most cases the timing belt might be the problem. You can fix this by pouring some oil into the cylinder.

If this works you may have also fixed the problem in the piston rings. To begin check for no compression in one of the cylinders with a compression gauge. Make sure you have enough time to complete the exam as it will take about 40 to 45 minutes.

Examine the cylinder gasket valves and piston to check if any of these components are broken or damaged after verifying that one of the cylinders has no compression. To begin use a compression gauge to determine whether one of the cylinders has no compression. The test will take around 40 to 45 minutes.

Thus make sure you have enough time to complete it. After determining that one of the cylinders has no compression inspect the cylinder gasket valves and piston to see if any of these components are cracked or damaged. How to Fix Low Compression in One Cylinder.

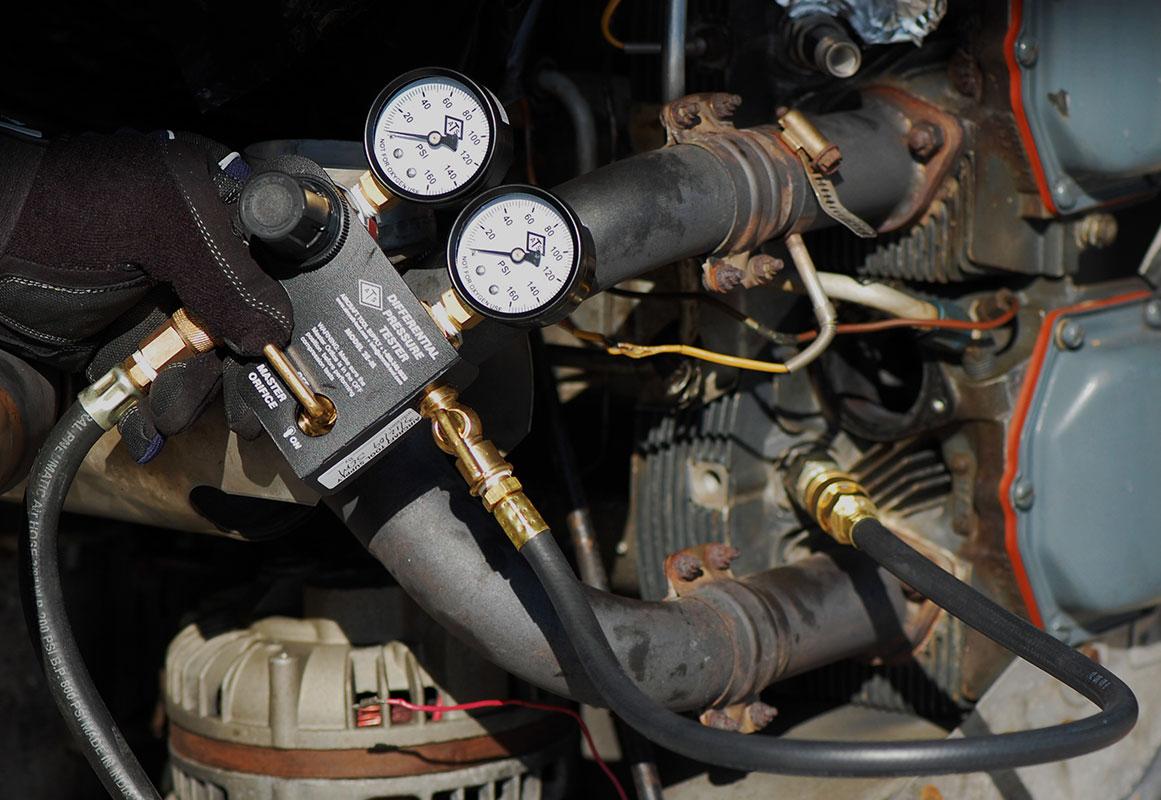

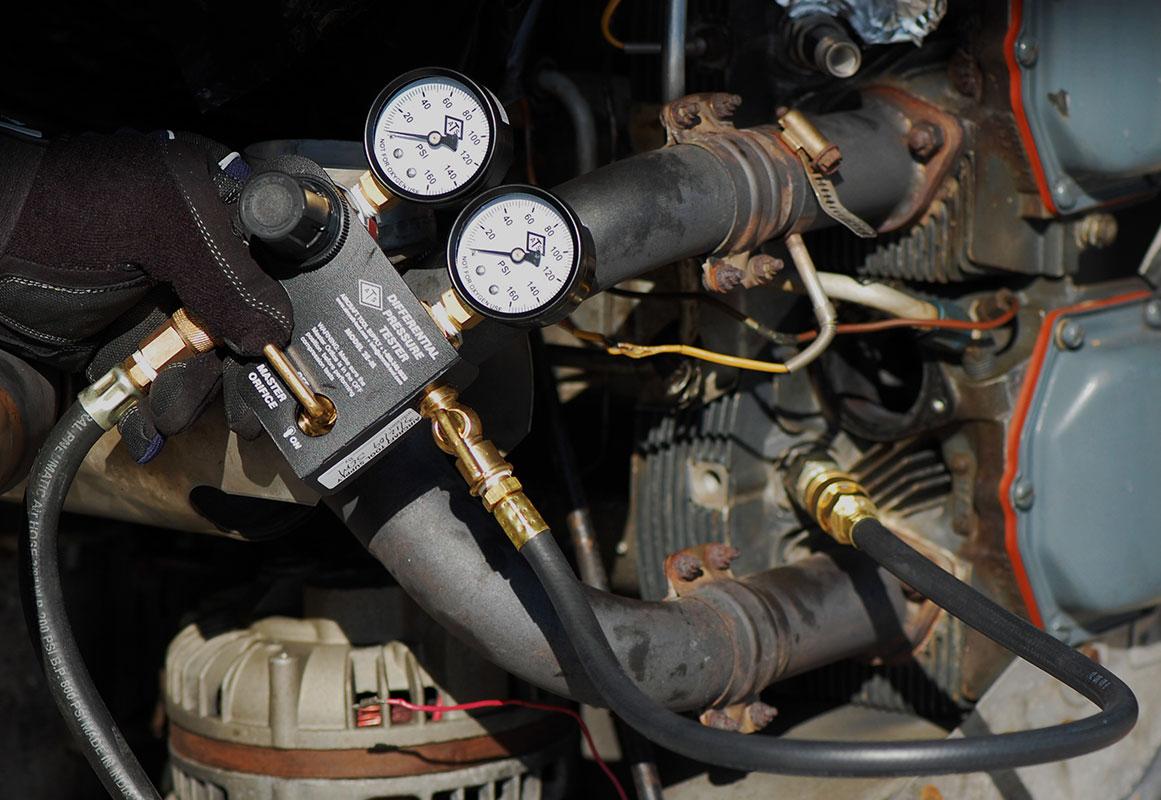

The first step to repair is to be sure that the compression in One of the engine cylinders is low. Use a compression gauge to check the measurement. In case you dont have one Take the car to an auto servicing shop.

So a mechanic can do the testing. If you find low compression the next step is to check the cylinder Valves gasket. I would pull the valve cover on the bank of the cylinder with no compression and do a visual check first.

You might find a broken valve spring or a pair of popped keepers. Jiggle the valve springs side to side to see if they feel loose. See if the valve is retracting to the full height.

If you dont have the time or budget for a physical hard part repair your next step should be adding an engine compression restoration treatment product such as Rislone Compression Repair with RingSeal to your engine. While a product like this does not guarantee you will never have a compression issue some compression issues are too severe and a hardware fix is the only repair. Cylinder 2 has no compression due to the valve spring not shutting.

If the valve spring is broke it can be replaced without removing the cylinder head. The labor guide shows 8 hours labor to replace the valve springs or valve seals on one bank they may charge less to replace just one valve spring. George_San_Jose1 January 4 2019 353am.

Discussion Starter 4 Feb 16 2013. BMWmini garage have said no compression in cylinder 1 however the timing is in spec. They want to charge 600 plus VAT to further diagnose the problem then the repair work could cost 2000 plus VAT.

How To Fix A Lawn Mower With No Compression - Video - YouTube. There are some relatively minor repairs that you can make to fix a low compression problem in a cars engine. For instance replacing bad piston rings will usually only cost somewhere between 40 to 200 per piston ring.

But thats going to be among the most affordable repairs for those with low car engine compression. If no compression is present in any one cylinder it means a mechanical malfunction has occurred while low compression could just be the sign of worn internal engine parts. Checking compression is done using a simple compression gauge and can be done in about 45 minutes in most cases.

Repair done by a professional mechanic to fix the low compression in one cylinder will normally cost you 100 to 200. This is with the repair alone but if you consider the replacement of other damaged parts the cost will surely vary. Repair of head gasket costs between 1000-2000.

In either of these events squirt a little oil into each cylinder. Then repeat the compression test. If the compression dramatically increases then you have found the problems.

If the compression readings do not change then it would indicate a timing problem. No Engine Compression In One Cylinder Dropped Valve Seat. Low compression can be caused by normal engine wear and decreased sealing between the piston rings and cylinder walls.

This can be the result of scratches in the cylinder walls or sticking rings in the pistons which allow compression to move from the top of the cylinder down into the crankcase below the piston. Once youve lost 60 percent or more of the compression in one cylinder its effectively dead or shaking the engine so badly that you cant ignore it. Low-compression engines wont develop enough cylinder pressure to sustain the fuel burn and ignite the whole mixture while high-compression or forced-induction engines will essentially shake themselves to pieces or otherwise act as though they have a.

You need to look at the inner insulator which is screwed into the cylinder head and the outer insulator on which the armature wire cap is put on. Check the high Voltage Wires The wires can be a culprit. Because of the harsh operating conditions they can get loose.

Plus poor labor can cause them to. Motorcycle Repair Building and Restoration. No compression on one cylinder.

Jump to Latest Follow 21 - 40 of 53 Posts. First 2 of 3 Go to page. Bpe Premium Member.

Joined Sep 5 2019 1982 Posts 21 Dec 15 2019. I think you are on the right track to get the valves adjusted first. It really depends why blown head gasket damaged valves weak piston compression rings take a compression of cylinder record reading then put 4 ounces of engine oil into the cylinder and test again if the compression comes up to were it should be its the piston and if it only has a minor change it is the valves or head gasket put 100 psi of air pressure into the cylinder on compression stroke and listen for.

It can take anywhere from five minutes to several hours or several days. In a single cylinder engine it can be as simple as a stuck valve. Take the head off spray some liquid wrench on the valve turn the engine over till the valve opens and tap it down with a small rubber hammer several times till it loosens up and closes by its self.