2 will work but you need to get exactly and I do mean exactly the right size also if your bolt is seized it will probably fail. Buy a proper set or better still drive round the garages until you find someone who has one.

This video shows how to cut a bolt and use the nut to repair the thread.

How to get a bolt off without the right tool. Hold the extra bolt horizontally over the bolt in question and then just screw on the nut until you have a nice tight grip on that annoying first bolt. Then you can use your incorrectly-sized wrench as a lever or handle so that you can unscrew to your hearts content without hurting your fingers. Go to an auto parts store and look for a Bolt Extractor its a nifty tool that screws in the same direction as the bolt unscrews and allows you to drill into stuck bolt and keep turning it tighter and tighter until the bolt comes free and out.

Using a high-speed rotary cutter or hacksaw create a slot across the head of the hex bolt and remove with a flathead screwdriver. Obviously this damages the bolt but it is a useful technique particularly when the bolt will be discarded or has become stripped. If the motor is in the carjack it up and put the car into neutral and stick screwdrivers into the slots on the discs of the brakes eventually the discs will turn and hit the calipers and lock the motor just use big enough screwdrivers and a breaker bar and a bar on the end of it or something.

You will need tools to get the spare tire down. An ignition key and a jack kit without the jack is an excellent place to start. If you do not know what a jack kit is look for a long pouch under the back bench seat.

It comes with a crowbar and several rods. You can get these from many places if you do not have the kit. For screws that are a bit larger you can use a drill and extractors.

This process is best when your bolt is stuck close to the surface that you cant manage to clamp pliers on. Drill a 18-inch hole in the center of the screws head. Then use the largest extractor that fits snugly to the hole you have drilled.

Remove the CVT cover as usual. Line this tool up with the teeth on the variator drive face. Then bolt the tool to the engine.

Now your variator is locked into place and you can use a ratchet or wrench instead of getting out the old impact gun. Try loosening the bolt with a wrench. If the bolt wont turn try tightening it and then loosening it.

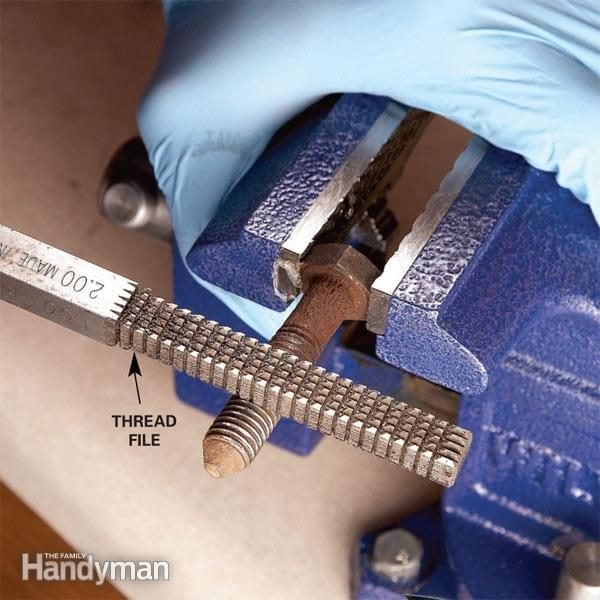

The back-and-forth action might jar it loose. This video shows how to cut a bolt and use the nut to repair the thread. Cutting a bolt to the correct length can be difficult as the thread is often damaged.

In most cases you can remove a bolt by unscrewing the nut from the bolt with a wrench. If the bolt is rusted or otherwise stuck in place however youll need to find another way to remove the bolt. If the hexagonal surfaces of bolt and nut havent been stripped try heating the bolt with a propane torch to loosen it.

2 will work but you need to get exactly and I do mean exactly the right size also if your bolt is seized it will probably fail. Bottom line do not be tempted by the removal tools you see in Halfords etc. Buy a proper set or better still drive round the garages until you find someone who has one.

Center punch the broken bolt as close to the center as possible. Using a hammer mark the center of the broken bolt with a center punch. This will help you drill into the center of the bolt as closely as possible putting you at less risk of damaging the threads of the broken bolt.

Youll have to channel your inner Houdini to get the spinning bolt out- youll have to pry it out twisting it simultaneously. Get your hands on a crowbar and pry the bolt out of the hole. Worse comes to worst youll have to drill the bolt out or using a metal-cutting bit to break and remove the bolt before replacing it.

If youre using any of these extreme measures youll need. Once the lug nuts are off the wheel you can jack up the car and replace the tire. Put the lug nuts back on the wheel but only make them finger tight.

Lower the car and get that old crossbar ready to use again. With the tire back on the ground use both hands to tighten the lug nuts in the proper order. It can be difficult removing a broken bolt or stud that is recessed in a deep hole as there are not many techniques to remove the bolts.

Tighten the pipe wrench down on the boltnut and as you crank on the bolt with the pipe wrench it actually grabs harder onto the bolt head. Just watch you knuckles if it slips off. Reinstall Bolts That Surround the Stuck BoltNut Sometimes a number of bolts in an area will hold a part on.

Occasionally these are meant to be removed in. Like I said take a couple extra minutes to prep that shaft. Once thats nice and clean you just grab something some sort of lubricant rust breaker WD-40 in this case.

Spray a little bit on there and nine times out of ten this wheel will come right offno problems at all without any puller. So thats what I do. How to Get a Toilet With a Stuck Bolt Off the Floor.

A typical toilet attaches to the floor with a pair of bolts that stick up from the flange a special fitting at. Right when youre giving a stuck bolt all your muscle wrenches will slip bolt heads will snap off and your hands will get smashed against something sharp. So always wear gloves and try to orient tool handles so your hands will be clear if a tool slips.

Shift your bicycle gear to the largest cog so that it wont get caught on your hands or arms. Make sure that your surrounding area is free from unnecessary objects such as a liquid that can spill or fall on you. Step 2 Remove the crank bolt or nut.

When you do this it loosens the crankset and bolt and lets you remove it with ease.