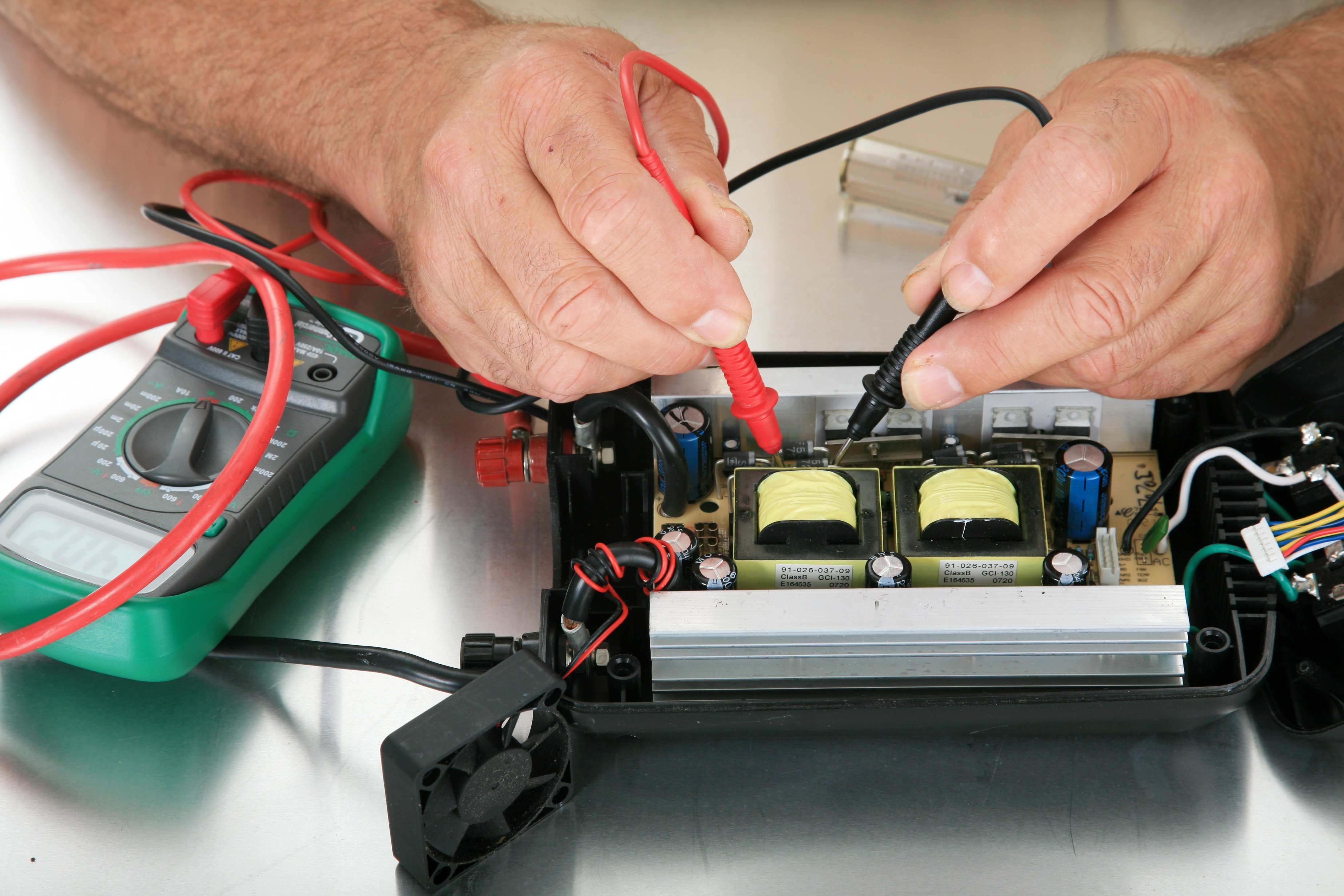

Testing pressure transducers at certain intervals is also a good practice to ensure that it is working well and within the right specifications. If a pressure transducer fails during use measure the raw voltage or amperage emitted by the transducer at no pressure and again at the pressure transducers full capacity.

Second you can use your sonar screen to tell if the transducer is level or not.

How to tell if transducer is bad. If your fish finder isnt performing as it should one possibility you need to consider is that the transducer isnt working properly. So how can you tell if the transducer is bad. Heres the quick answer.

First of all check the transducer for damage or dirt on its surface. If you find dirt or barnacles clean it gently. Signs and Symptoms Of A Faulty Transducer.

A fluctuating or incorrect output is one of the first signs thatll giveaway for a bad transducer for both Boat Sonar Transducers and Pressure Transducers. If the transducer is bad itll generate faulty output signals that show you display readings incorrectly. There are several ways that you can know whether your transducer is in a bad state.

If you suspect that something may be wrong with it start by checking its surface to detect any dirt or damage. Next check whether its orientation is appropriate with the right side up. Wrong positioning may affect its functioning.

There are many things that can cause a transducer to provide unstable readings examples include shock overload lightning or electrical surges mis-handling water ingress corrosion broken cable short circuit. Why does my torque transducers shaft not. If a pressure transducer fails during use measure the raw voltage or amperage emitted by the transducer at no pressure and again at the pressure transducers full capacity.

If theres no change in the signal you can determine that the transducer is not responding to pressure. Most SONAR transducers have a piezoelectric element which will not have DC continuity. The DC resistance will be extremely high too high to measure with simple equipment.

The most reasonable way to test a SONAR system is to test the transducer and the head unit by swapping them out for replacement units that are known to be good. The best way to test a transducer is to put another unit on it and see what that unit does. This works great if you have another unit or know.

For most models if the receiver doesnt detect the transducer a digital message on the display will indicate this. Sonar data should appear if you dont hit a button to perform another option first. If you can see the bottom on the digital screen and it gives you the depth numbers then your device is good to go.

This is particularly important with a newly installed transducer. Recheck every two to three hours for the first day or two after the install. If there is a leak haul the boat as soon as possible and have it fixed.

Periodically inspect the transducer connectors for signs of corrosion and inspect the cable for cuts in the insulation. This happens because the transducer tries to send and receive sound signals as if it were submerged in water but is only able to pick up random noise which the processor cant interpret correctly. Also as mentioned above turning on your depth finder out of water can damage the transducer so its definitely not a good way to test it.

Yup Id bet it is time for a new transducer. What causes them to go bad. Collisions with junk in the water big and small are one cause.

Poor design and construction are another. Some brands have a track record of needing to replace transducers far too frequently. If you install a faulty pressure transducer you are likely to get false pressure data which can lead to undesirable results.

Testing pressure transducers at certain intervals is also a good practice to ensure that it is working well and within the right specifications. Follow the steps mentioned below to test a pressure transducer. Learn how to tell if a pressure transducer is working properly.

Find out what to look for on both a residential and commercial VFD as well as how to diagnos. Second you can use your sonar screen to tell if the transducer is level or not. Heres a few quick tips.

If you cant see anything at all then level the transducer. In 2D sonar If you can see some sort of arch and all the arches are tilted forward or backwards then the transducer is not level theres an example in the video. If the pressure is not right then the AC system will not be able to produce the cold air required to adequately cool the cabin.

You may notice that the cabin takes longer than usual to reach the correct temperature or may not even be able to reach the correct temperature at all. Compressor not coming on. The normal operating values for the force transducer during calibration should be between 3000 and 3500.

If the value is 0 a single digit or a three digit number the force transducer is broken and needs to be replaced. If the value is less than 2000 or greater than 4500 the force transducer is broken and needs to be replaced. Lets take a look at the most common signs of a bad AC pressure switch.

The most common symptom of a bad AC pressure switch is a faulty or intermittent air condition function. In most cases you will notice this during hot days when there is. The best way to check this is to have someone go over the side and take a look at the transducer to check for growth of grass barnacles or worse.

If that isnt possible take the depth sounder to your local service dealer and have it checked out on the bench. If you have a transducer with a built-in driver. Which you want to measure the frequency then you can do as you suggest.

Or you can just connect the driver output to an oscilloscope and look at the waveform. If you do not know the frequency response of these transducers then the method I provided will give you a close-enough idea. Signs of a Bad Ethernet Cable Everything You Need to Know.

Just like anything in the world wears out one day or the other so does happens with the Ethernet cables. Unfortunately they are never going to last for you forever and eventually wear and tear out due to all the external factors assisting the decay process. Divide this figure by the supply voltage in this case 10Vdc Check this figure to the zero balance of the calibration certificate provided by your supplier.

If the zero balance figure is significantly different to the calibration certificate this could indicate that. If the new transducer gives the same result - the transducer is good. If not the original transducer is bad.

Pretty cut and dried. Transducers can fail in many different ways. The connector at the depth finder can go bad due to a broken plastic lock or a bad corroded or missing pin on the connector itself.