Never use an impact wrench when tightening or loosening lug nuts or bolts during the procedure. Generally with any castle nuts you tighten it hand tight and back it off to the nearest hole that the pin will fit into however make sure the hub is tight on the axle and that theres not a half inch of.

Tighten the spindle nut finger tight until snug and then with channel-lock pliers or a crescent wrench tighten the spindle nut another 14 turn or about 15 to 20 ft pounds of torque.

How to tighten trailer wheel bearings. How to tighten trailer wheel bearings - YouTube. How to tighten trailer wheel bearings. In this video I will show you how to adjust the bearings on your trailer the EASY way.

Follow me on Instagram. After youve packed the bearings and assembled everything carefully slide the hub assembly onto the spindle and install the outer bearing. Install the spindle and tang washer and run the spindle nut down finger tight then rotate the hub back and forth then rock the hub side to side to make sure everything is seated properly.

Lubricate the tapered roller bearing with clean axle lubricant of the same type used in the axle sump or hub assembly. Never use an impact wrench when tightening or loosening lug nuts or bolts during the procedure. These designs use an engineered spacer between the bearings to achieve the correct bearing settings by simply applying a certain.

To pre-load the bearings install the spindle washer and spindle nut onto the spindle with the hub and bearings in place. Tighten the spindle nut finger tight until snug and then with channel-lock pliers or a crescent wrench tighten the spindle nut another 14. To pre-load the bearings install the spindle washer and spindle nut onto the spindle with the hub and bearings in place.

Tighten the spindle nut finger tight until snug and then with channel-lock pliers or a crescent wrench tighten the spindle nut another 14 turn or about 15 to 20 ft pounds of torque. Install washer and tighten axle nut so there is no movement in the bearing be careful to not over tighten axle nut. Hub should spin freely with no vertical or horizontal rocking.

Replace with a new split pin and ensure the legs are bent around the axle nut so it wont fall out. Replace tyre and wheel nuts. Always check the service information for the correct procedure.

Over tightening adjustable tapered roller bearings can lead to premature failure. Never preload tapered roller bearings on the front of RWD vehicles. Theyre snugged up with no more than 15 to 20 ft.

Of torque while rotating the wheel to make sure the bearings are seated. The adjustment nut is then loosened. If the bearings are the taper roller type you should tighten the nut about 30 degrees passed the point when the bearing is seated turning the wheel as you tighten to ensure the bearing is seated.

Then undo the nut until you can just feel a tiny amount of play. No pressure on the bearing. Screw the trailer wheel lug nuts onto the wheel studs and hand-tighten with the trailer tire iron.

Remove the jack-stands from under the trailer axle and frame and slowly release the jack to lower. Along with bearing adjustment proper lubrication is essential to the proper function and reliability of your trailer axle. Bearings should be lubricated every 1 months or 1 000 miles.

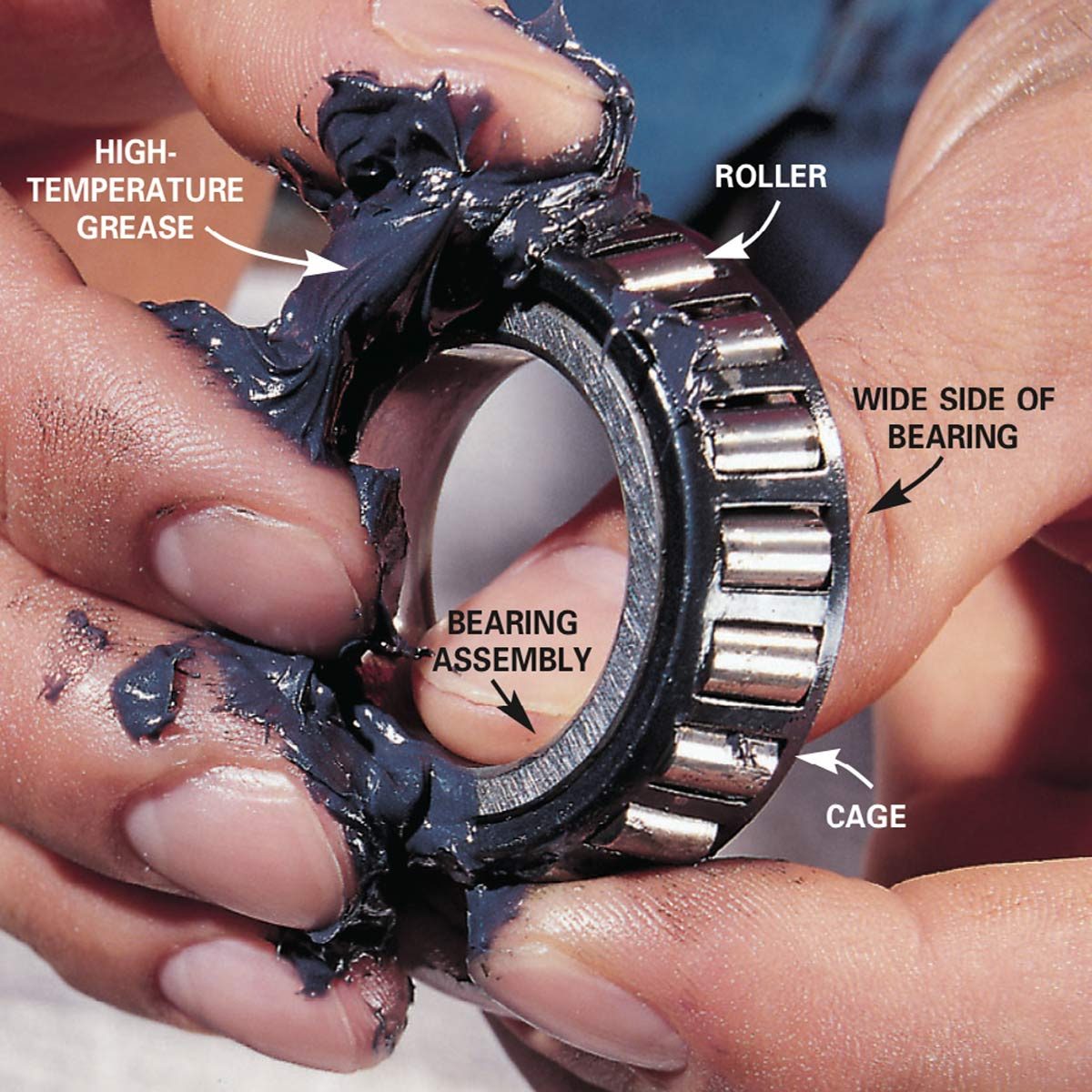

The method to repack bearing cones is as follows. Place a quantity of grease into the palm of your hand. Press a section of the widest end of the bearing into the.

Take 1 wheel off the trailer to access the hub assembly. Loosen the nuts on all wheels with a lug wrench while the trailer is on the ground. Jack the trailer up just enough to lift the wheels off the ground.

Finish unscrewing the nuts on 1 wheel with the lug wrench remove them and slide the wheel off the hub. You will need to use a lifting jack such as a bottle jack to get the trailer. And its always recommended to replace the rear grease seals behind each bearing.

To properly set the assembly snug up the castle nut. Though one may exist Ive never seen a published torque spec for tightening the castle nut to the spindle but if you spin the tires in the opposite direction as you tighten the castle nut snug you should be fine. The nut on the spindle should be tightened until snug with no side-to-side play in the hub and then backed off slightly about maybe a 18 of a turn.

If the spindle uses a castle nut and cotter pin or tang nut tighten the nut finger tight until it stops then back it off so the cotter pin or washer tang fits into the next indentation of the. Unlike sealed wheel bearings the front wheel bearings found on a typical rear-wheel-drive car or truck employ two-piece caged bearing assemblies. Good maintenance dictates that the bearings should.

Ive seen to types of wheel bearings most with cotter pins and castle nut and few weeks ago i put electric brakes on an old beast of a trailer that had just a nut not a castle nut. Generally with any castle nuts you tighten it hand tight and back it off to the nearest hole that the pin will fit into however make sure the hub is tight on the axle and that theres not a half inch of. 18 top to bottom movement is fine.

Tighten the nut to 50 lbft while rotating the hub to ensure the bearings are seating properly then loosen the nut off and tighten it hand tight. If the cotter pin wont line up back off to the next hole dont go tighter. Kubiak Oct 4 2012.

To meet correct end play specifications follow this six-step procedure for nut torquing and back off. Torque the adjusting nut to 200 lbf-ft while oscillating the wheel. This will fully seat the bearing components.

Back off the adjusting nut one full turn or until it is loose. Secure the load to the trailer with tie downs. Check tire pressure while the tires are cold.

Check and adjust wheel bearings if necessary after the first 50 miles of use. Inspect and repack wheel bearings as needed. Check that the bed locking pin is in place for trailers.